The Opti-Rate Spring System

Share

Leaf springs are probably the oldest, continuously used form of suspension. That would lead one to think that they must be something super simple and well understood, but in reality the opposite is true, and there is a lot more going on than meets the eye. At their core, a leaf spring is a stack of metal strips designed to carry a load via spring force, locate the axle under the chassis, and control acceleration, braking and lateral forces on the suspension. The spring's length and arch, the quantity and thickness of each leaf, the engagement points between the tips and the leaves above, even the material and post processing like peening and heat treatment will all have subtle effects on the spring's rate and installed height. Spring rate and spring arch are not the same, as it's entirely possible to have a spring with a lot of arch but a low rate or a flat spring with a very high rate, and vice versa.

Sprinters use a parabolic spring, which features a pair (or 3, on 3500) of tapered leafs, that engages force through the tips. These serve the basic purpose of holding the vehicle up, holding the axle in place and can carry a load as intended with a low manufacturing cost, but have limited options for modifications to ride height, rate, and are quickly overwhelmed by going over gross weight ratings as is often the case with RVs.

What is sag?

As weight is added to a vehicle, the suspension will naturally compress and squat down. Over time, carrying weight will also cause spring fatigue and the spring will sit even lower. We define 'sag' as lost ride height. Maintaining proper ride height is critical for proper handling. Vehicles are designed from the factory to sit in a range, where a generally equal amount of compression (up) and droop (down) travel are maintained. This ensures good compliance and damper progression for everything to work around terrain and driving forces. Shifting away from this equilibrium in either direction can have dramatic effects on a vehicles handling and performance. With a built out van, it's important to correct the spring rate to the van's full time weight so that the attitude of the vehicle is 'neutral' and close to the original intentions of the manufacturers. It's also important to not add too much ride height and throw the balance in the opposite direction of sag, and run the suspension near top out where limited droop is available and compliance and stability reduced.

Further, since the leaf is not only holding the vehicle up, but also locating the rear axle, they are an important component of the overall stability of the vehicle. An overloaded, or sagging van is going to wander more and will not track as smoothly when it is overwhelmed by the extra weight. The spring is also balancing the torque of the engine input by the driveshaft, and being overloaded on weight can cause the spring to fatigue more quickly from the combined forces.

One spring to rule them all.

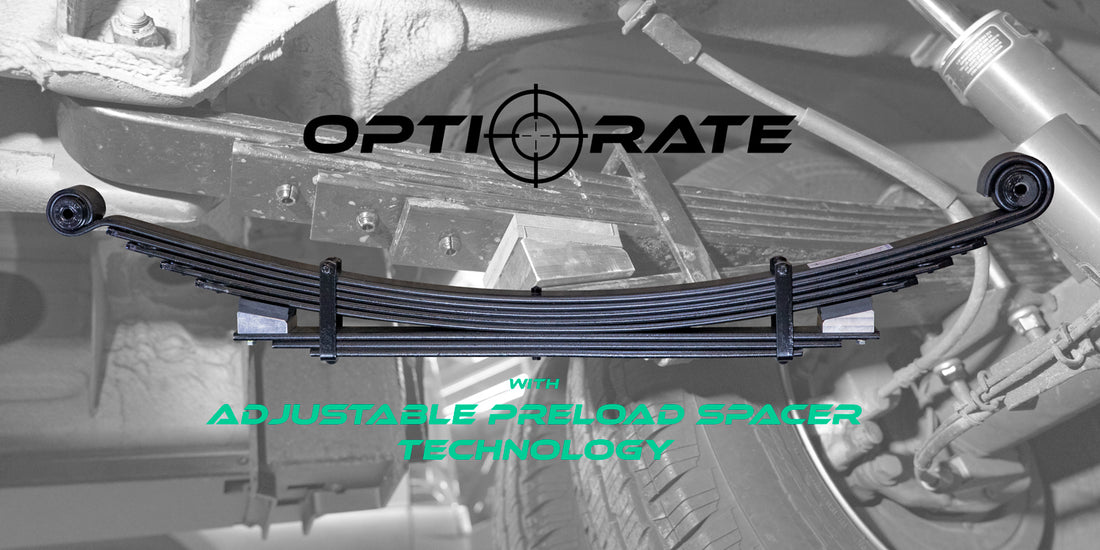

Our Opti-Rate spring system represents a revolution of how a leaf spring can be designed, used and sold. We deal with a wide range of van weights and owner preference for ride height or vehicle stance. It wouldn't seem like one spring could be made to work across a huge range of vans but that's exactly what we set out to do. The reasoning, is two-fold. First, it will allow our dealers to easily stock a spring that works across the range, without having to individually weigh each van and then order a specific springs which can create bottle necks of availability. Second, many customers are upgrading their suspension first, or mid-way through the build journey. Providing them a future-proof option is important to us, since it allows them to reap the benefits of a tuned suspension for longer and sooner. Third, existing options mandated a roughly 2" lift, which is more than many customers want, and works best with corresponding components added to correct the geometry of the other moving parts.

But how does it work?

Multi-stage springs are actually a pretty common thing, and have been around for probably 100 years. Most of us have seen a typical 1-ton or commercial truck and the enormous rear spring packs they have. Usually, there is a very thick overload, and helper leaves sitting on top of the main leaf that engage on frame pads as a load is added. A popular aftermarket solution to the same problem is air bags. These all serve to protect and augment the main springs, since the fastest way to damage a spring pack is to over load it frequently. The overload and helper leaves add spring rate as needed, when load is added. While this solution seems easy, it really only works well (or safely) on a vehicle with a thick steel ladder frame, which the unibody Sprinter does not have. Therefore, the spring force loads really need to be directed into the chassis through the Mercedes engineered mounting points for the leaf springs.

Using a combination of a main leaf pack, and an overload pack beneath it that is tuned to match, we've created a system that can have the spring rate changed easily without removal. Billet machined Adjustable Preload Spacers (APS) fit on the tips of the lower helper spring and engage the spring as a complete unit. Configurable in 3 ways, this allows for 3 distinct spring rate options depending on the customer's needs.

Here, we can see 3 different configurations at the same van weight (2200lb pallet directly over rear axle). The stock spring is overloaded, and the van is over GVWR. The Opti-Rate spring restores lost ride height without the APS, and when the APS is added a tail-high rake is achieved.

Without the APS installed, the springs work like a standard 6-leaf pack, and net about 1" of lift with the factory 4x4 block removed. With the APS installed and 1 delrin slider on it, the second rate configuration is engaged. The spring rate is increased, as well as the relative ride height. With 2 layers of delrin sliders installed on the Adjustable Preload Spacer, the third and stiffest option, will be engaged. This puts the spring in it's tallest, highest rate configuration and preloads the lower helper pack into the main spring pack. As you can see from the below images, even with wide variances in van weight, we're able to get the same end ride height from these springs, depending on how the overload pucks are configured.

The real beauty of the Adjustable Preload Spacer system is that once the leaf springs have been installed, the spring rate can be fine-tuned without complete disassembly of the spring. Previously, the only way to tune a leaf spring meant that the springs had to be completely disassembled, a complicated and lengthy process that often required having multiple spring options available.

Fitment is available for both the 2500 and 3500 Sprinters, click the link below to be taken to the product page.

2500 Sprinter 4x4 Opti-Rate Rear Leaf springs

3500 Sprinter 4x4 Opti-Rate Rear Leaf springs